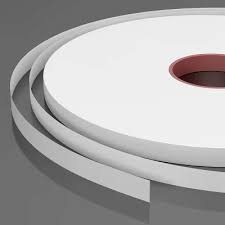

Acetate tow is a form of cellulose acetate used primarily in the production of cigarette filters. It is made from cellulose, which is a natural polymer derived from wood pulp or cotton linters, and is then chemically modified to produce cellulose acetate. The process involves acetylation, where acetic anhydride is used to introduce acetyl groups into the cellulose, resulting in a plasticized and fibrous material.

Key Characteristics and Uses of Acetate Tow:

1. Filtration Efficiency Acetate tow is highly effective in filtering out particles and tar from cigarette smoke, making it the most common material used for cigarette filters.

2. Softness and Density: The fibers are fine and soft, providing a comfortable feel while maintaining a sufficient density to serve as an effective filter.

3. Biodegradability: While not entirely biodegradable, acetate tow is more environmentally friendly than some synthetic alternatives, breaking down more readily under certain conditions.

4. Versatility: Besides cigarette filters, acetate tow is used in various other applications, including air and liquid filtration, medical supplies, and textiles.

5. Production Process: – Cellulose Source: Derived from wood pulp or cotton linters.

– Acetylation: The cellulose is treated with acetic anhydride in the presence of sulfuric acid or another catalyst to produce cellulose acetate. –

Dissolution and Spinning: The cellulose acetate is dissolved in a solvent, usually acetone, and then extruded through a spinneret to form fine filaments. –

Tow Formation: These filaments are then bundled together to create a continuous tow, which can be crimped and cut to the desired length.

6. Market and Economic Impact: Acetate tow is a significant product in the tobacco industry, contributing to the economic activity associated with cigarette manufacturing.

Environmental Considerations: Although acetate tow is more environmentally friendly compared to some synthetic materials, the disposal of cigarette filters remains a significant environmental concern. Efforts are ongoing to develop more sustainable alternatives and improve the biodegradability of filters.

Reviews

There are no reviews yet.